Table of Contents

फ्याक्ट्री सञ्चालनमा एलडी इलेक्ट्रिक सिंगल बीम क्रेन किट प्रयोग गर्ने फाइदाहरू

सिरियल नम्बर

| उत्पादनहरू | 5~400T नयाँ-प्रकार ओभरहेड क्रेन हुकसँग |

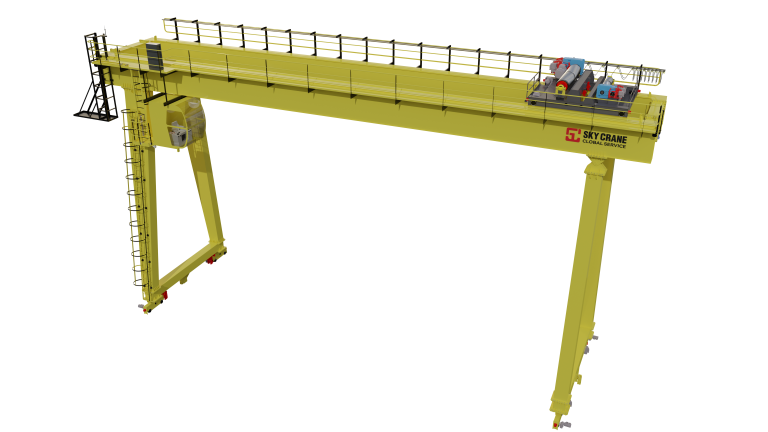

| 1 | L-प्रकार गैन्ट्री क्रेन |

| 2 | युरोपेली शैली क्रेन |

| 3 | हार्बर क्रेन |

| 4 | तपाइँको कारखानाको लागि दायाँ LD इलेक्ट्रिक सिंगल बीम क्रेन किट कसरी छनौट गर्ने |

फ्याक्ट्री सेटिङहरूमा LD इलेक्ट्रिक एकल बीम क्रेन किटको लागि मर्मत सुझावहरू

सर्वप्रथम र प्रमुख कुरा, यो झर्ने र आँसुको कुनै पनि संकेतहरूको लागि नियमित रूपमा क्रेन निरीक्षण गर्न महत्त्वपूर्ण छ। यसमा ढीलो बोल्टहरू, क्षतिग्रस्त तारहरू, र थकित-आउट कम्पोनेन्टहरूको लागि जाँच समावेश छ। थप क्षति रोक्न र क्रेनको सुरक्षित सञ्चालन सुनिश्चित गर्न कुनै पनि समस्यालाई तुरुन्तै सम्बोधन गरिनुपर्छ। उचित स्नेहनले घर्षण र पहिरन कम गर्न मद्दत गर्दछ, उपकरणको आयु विस्तार गर्दछ। प्रत्येक कम्पोनेन्टको लागि आवश्यक स्नेहनको प्रकार र आवृत्तिको लागि निर्माताको दिशानिर्देशहरू पालना गर्न सिफारिस गरिन्छ।

अर्को महत्त्वपूर्ण मर्मत टिप नियमित रूपमा क्रेनको विद्युतीय प्रणाली जाँच गर्नु हो। यसले क्षति वा खराबीको कुनै पनि संकेतको लागि तार, जडान, र नियन्त्रण प्यानलको निरीक्षण समावेश गर्दछ। विद्युतीय प्रणालीको कुनै पनि समस्यालाई विद्युतीय खतराहरू रोक्न र क्रेनको उचित कार्यसम्पादन सुनिश्चित गर्नको लागि एक योग्य इलेक्ट्रीशियनद्वारा सम्बोधन गर्नुपर्छ।

यसबाहेक, यो क्रेनको सुरक्षा सुविधाहरू, जस्तै सीमा स्विचहरू र ओभरलोड सुरक्षा उपकरणहरू नियमित रूपमा जाँच गर्न महत्त्वपूर्ण छ। यी सुरक्षा सुविधाहरू दुर्घटनाहरू रोक्न र उपकरण र कर्मचारी दुवैको सुरक्षा गर्न डिजाइन गरिएको हो। यी सुरक्षा सुविधाहरूको नियमित परीक्षण र मर्मतसम्भार तिनीहरूले ठीकसँग काम गरिरहेका छन् भनी सुनिश्चित गर्न आवश्यक छ। धूलो, फोहोर, र अन्य प्रदूषकहरूले उपकरणलाई क्षति पुर्याउन सक्छ र यसको कार्यसम्पादनलाई असर गर्न सक्छ। होइस्ट, ट्रली र रनवे सहित क्रेनको नियमित सफाईले समस्याहरू रोक्न र सहज सञ्चालन सुनिश्चित गर्न मद्दत गर्न सक्छ। यसका अतिरिक्त, अपरेटरहरूलाई उचित क्रेन प्रयोग र मर्मत प्रक्रियाहरूमा तालिम दिनु महत्त्वपूर्ण छ। अपरेटरहरू उपकरणको क्षमता र सीमितताहरू, साथै आधारभूत मर्मत कार्यहरू कसरी गर्ने भनेर परिचित हुनुपर्छ। उचित प्रशिक्षणले दुर्घटनाहरू रोक्न र क्रेनको सुरक्षित सञ्चालन सुनिश्चित गर्न मद्दत गर्न सक्छ। यी मर्मत सुझावहरू पछ्याएर, कारखाना मालिकहरू र अपरेटरहरूले उपकरणको आयु लम्ब्याउन, महँगो ब्रेकडाउनहरू रोक्न, र कर्मचारीहरूको सुरक्षा सुनिश्चित गर्न सक्छन्। सधैं निर्माताको दिशानिर्देशहरू परामर्श गर्न र क्रेनको उचित मर्मत सुनिश्चित गर्न आवश्यक पर्दा व्यावसायिक मद्दत खोज्न सम्झनुहोस्।

When it comes to choosing the right LD electric single beam crane kit for your factory, there are several factors to consider. LD electric single beam cranes are commonly used in factories and industrial settings for lifting and moving heavy loads. These cranes are known for their efficiency, reliability, and ease of use. However, with so many options available on the market, it can be overwhelming to choose the best one for your specific needs.

One of the first things to consider when selecting an LD electric single beam crane kit is the weight capacity. It is essential to determine the maximum weight that the crane will need to lift on a regular basis. This will help you choose a crane that is capable of handling the loads in your factory without any issues. It is always better to choose a crane with a higher weight capacity than you think you will need to ensure that it can handle any unexpected heavy loads that may arise.

Another important factor to consider is the span of the crane. The span is the distance between the two runways on which the crane travels. The span of the crane should be determined based on the layout of your factory and the distance that the crane will need to travel to lift and move loads. It is crucial to choose a crane with the appropriate span to ensure that it can reach all areas of your factory without any limitations.

In addition to weight capacity and span, it is also essential to consider the lifting height of the crane. The lifting height is the maximum height to which the crane can lift loads. It is crucial to choose a crane with a lifting height that is suitable for the height of your factory and the height at which loads need to be lifted. Choosing a crane with a lifting height that is too low can limit its functionality, while choosing one with a lifting height that is too high can be unnecessary and costly.

Furthermore, it is important to consider the speed and control features of the crane. LD electric single beam cranes come with various speed and control options, such as single speed, dual speed, and variable speed controls. The speed and control features of the crane should be chosen based on the specific requirements of your factory and the type of loads that need to be lifted and moved. It is essential to choose a crane with the appropriate speed and control features to ensure smooth and efficient operation.

Lastly, it is crucial to consider the quality and reputation of the manufacturer when choosing an LD electric single beam crane kit. It is important to choose a crane from a reputable manufacturer that has a proven track record of producing high-quality and reliable cranes. A crane from a reputable manufacturer is more likely to be durable, efficient, and long-lasting, saving you time and money in the long run.

In conclusion, choosing the right LD electric single beam crane kit for your factory requires careful consideration of factors such as weight capacity, span, lifting height, speed and control features, and the reputation of the manufacturer. By taking these factors into account, you can select a crane that meets your specific needs and ensures smooth and efficient operation in your factory.

Maintenance Tips for LD Electric Single Beam Crane Kit in Factory Settings

Maintaining an LD electric single beam crane kit in a factory setting is crucial to ensure the safety and efficiency of operations. Regular maintenance not only prolongs the lifespan of the equipment but also helps prevent costly breakdowns and accidents. In this article, we will discuss some essential maintenance tips for LD electric single beam crane kits in factory settings.

First and foremost, it is important to regularly inspect the crane for any signs of wear and tear. This includes checking for loose bolts, damaged wires, and worn-out components. Any issues should be addressed immediately to prevent further damage and ensure the safe operation of the crane.

In addition to visual inspections, it is also important to perform regular lubrication of the crane’s moving parts. Proper lubrication helps reduce friction and wear, extending the lifespan of the equipment. It is recommended to follow the manufacturer’s guidelines for the type and frequency of lubrication required for each component.

Another important maintenance tip is to regularly check the crane’s electrical system. This includes inspecting the wiring, connections, and control panel for any signs of damage or malfunction. Any issues with the electrical system should be addressed by a qualified electrician to prevent electrical hazards and ensure the proper functioning of the crane.

Furthermore, it is important to regularly check the crane’s safety features, such as limit switches and overload protection devices. These safety features are designed to prevent accidents and protect both the equipment and personnel. Regular testing and maintenance of these safety features are essential to ensure they are functioning properly.

It is also important to keep the crane clean and free of debris. Dust, dirt, and other contaminants can cause damage to the equipment and affect its performance. Regular cleaning of the crane, including the hoist, trolley, and runway, can help prevent issues and ensure smooth operation.

Additionally, it is important to train operators on proper crane usage and maintenance procedures. Operators should be familiar with the equipment’s capabilities and limitations, as well as how to perform basic maintenance tasks. Proper training can help prevent accidents and ensure the safe operation of the crane.

In conclusion, regular maintenance of LD electric single beam crane kits in factory settings is essential to ensure the safety and efficiency of operations. By following these maintenance tips, factory owners and operators can prolong the lifespan of the equipment, prevent costly breakdowns, and ensure the safety of personnel. Remember to always consult the manufacturer’s guidelines and seek professional help when needed to ensure the proper maintenance of the crane.