Table of Contents

Beneficium Usurae Pontis Metallurgici Crane in Applications Industrial

Key Features and Commoda of Rail-mounted Continens Gantry Crane

Aliud notam clavis rail-ectis continentis ganeae grues est earum efficacia in vasis tractandis. Eaedem grues ad maximize productivity et extenuo downtime designantur. Vasa celeriter et accurate movere possunt, reducendo tempus quo id onerare vel exonerare navem capit. Haec efficientia adiuvat portus et terminales ad cedulas strictas occurrendas et altiore perficiendo operando meliores.

Rail-escendae grues vas ganeae sunt etiam instructae notis provectis ad tuendos operarios et onerarias. Grues hae ordinantur ad condiciones environmental duras sustinendas, sicut venti validi et pluviae graves. Etiam sensoriis et terroribus instruuntur ad cooperatores cuiuslibet potentiae discriminis. Hic focus in tuto adiuvat ad impedienda accidentia et lenis ciconia operationem curabit.

Una praecipuorum commodorum est facultas vasorum variarum magnitudinum et ponderum tractare. Grues hae vexillum vascula levare possunt ac vascula aucta vel aucta, quae apta variis oneribus ad negotia tractanda facienda sunt.

Grues rail-escendae ganeriae vasculae in longo spatio etiam efficaces sunt. Dum notabilem collocationem initialem requirunt, hae grues sunt durabiles et certae. Longam vitam habent servitii et minimam sustentationem requirunt, impensas pretia temporis minuentes. Hoc facit incensae ganeae continens ganeiae captiosam obsidionem pro portubus et terminalibus spectantes ad eorum efficientiam et efficientiam emendandam.

No.

Product Name

| LX electricum suspensio gruis | MH eculeus gruis |

| 1 | brunculus europaeus-stylus |

| 2 | Portus grus |

| 3 | In fine: grues cancelli vasis ganeiae sunt necessarii instrumenti pro portubus et terminalibus quae magna continentium volumina tractant. Grues hae lineamenta clavis praebent ut capacitatem attollendi gravem, mobilitatem, efficientiam, salutem. Plura etiam commoda praebent, inclusa facultates varias vasorum et sumptus-efficentiae tractandi. Altiore, gantry grues rail-escendae continens res pretiosae sunt pro quolibet portu vel terminali spectantes ad streamline suas merces tractandas operationes. |

| 4 | Comparatio Pontis Metallurgici Crane et Rail-entis continens Gantry Crane in Materiali Tractantem Operations |

Pos metallicus grues et grues cancelli continentis ganeae sunt duo genera gruum gravium officiorum quae communiter in operationibus materialibus adhibentur. Dum ambo inserviunt oneribus sublevandis et movendis, differentiae praecipuae sunt inter duas quae singulas applicationes ad specificas aptas faciunt. Grues metallurgicae pontis in usum in plantis metallurgicis, fundamentis, aliisque industrialibus fundis ubi altae temperaturae et industriae designantur. ambitus asperos communes sunt. Eaedem grues peculiaribus notis instructae sunt, ut clypeorum caloris, systemata refrigeratio, et tunicae tutelae ad extremas condiciones sustinendas. Praecipua utilitas pontis metallurgici gruum est facultas operandi in ambitibus ubi grues normae efficaciter fungi non possunt.

Contra grues cancelli continentis ganeliae vulgo in portubus et in vase terminalibus ad onerandas et exonerationes adhibentur. naviculas continentia ex aliquet et navibus. Grues hae in cancellis ascenduntur et per longitudinem navalis movere possunt ad vasa in diversis navibus vel aliquet. Craues cancellatae vas ganeae notae sunt propter efficientiam et celeritatem in tractandis magnis vasorum voluminibus in brevi temporis quantitate.

Unus e praecipuis differentiis inter grues metallurgicos et rail-etas continens ganeae grues est mobilitas eorum. Grues metallurgicae de more stativae sunt et in certo loco intra facilitatem installantur. E contra, grues rail-eentes continentis ganeliae mobiles sunt et per cancellos moveri possunt ad diversas partes portus vel terminales pervenire. Haec mobilitas permittit grues rail-eentes continens ganeliae ut plures continentes et augeat fructibus in ambitu actuoso portu.

Alia differentia inter duplicem genera gruum est capacitas elevatio. Grues metallurgici ordinantur onera gravia in uncinis industrialibus levare, facultates elevare a paucis talentis ad plures centum talenta vagantium. Contra grues cancellatae vasis ganeliae, specialiter destinatae sunt ad tractandas naves naviculas, cum facultates elevatis typice ab 30 ad 70 talentis vagantibus. Grues altiores facultates pontis metallurgici levandi eas aptas ad grave officium levandi applicationes facit, cum grues rail-eentes vas ganeiae optimizantur ad vasorum efficaciter tractandum.

In operatione pontis metallurgici grues solent operari cabi operante, qui ciconia moderatur ex cella vel casula in gruibus ipsa sita. Grues cancellatae continentis ganeliae, contra, saepe longinque operatae sunt utens systema dicione computatrali. Hoc permittit operariorum monitorem et gruem ex longinquo tuto regere, salutem meliorem et efficaciam in tractandis operationibus continentis.

Demum grues et pontis metallurgici, et grues rail-eentes continentis ganeae magnas partes agunt in rebus materialibus tractandis, singulis cum suis. propriis commodis et applicationibus. Grues metallurgicae pons sunt ideales ad gravem officium elevatum in asperis ambitibus, cum grues rail-escendae continentis ganeliae praestant in vasis naviculariis in portubus et terminalibus tractandis. Inter has duas species gruum differentias intelligendas possunt negotiis iuvare rem aptam eligere ad eorum specificas materias tractandas necessitates.

Comparison of Metallurgical Bridge Crane and Rail-Mounted Container Gantry Crane in Material Handling Operations

Metallurgical bridge cranes and rail-mounted container gantry cranes are two types of heavy-duty cranes commonly used in material handling operations. While both serve the purpose of lifting and moving heavy loads, there are key differences between the two that make each suitable for specific applications.

Metallurgical bridge cranes are designed for use in metallurgical plants, foundries, and other industrial settings where high temperatures and harsh environments are common. These cranes are equipped with special features such as heat shields, cooling systems, and protective coatings to withstand extreme conditions. The main advantage of metallurgical bridge cranes is their ability to operate in environments where standard cranes would not be able to function effectively.

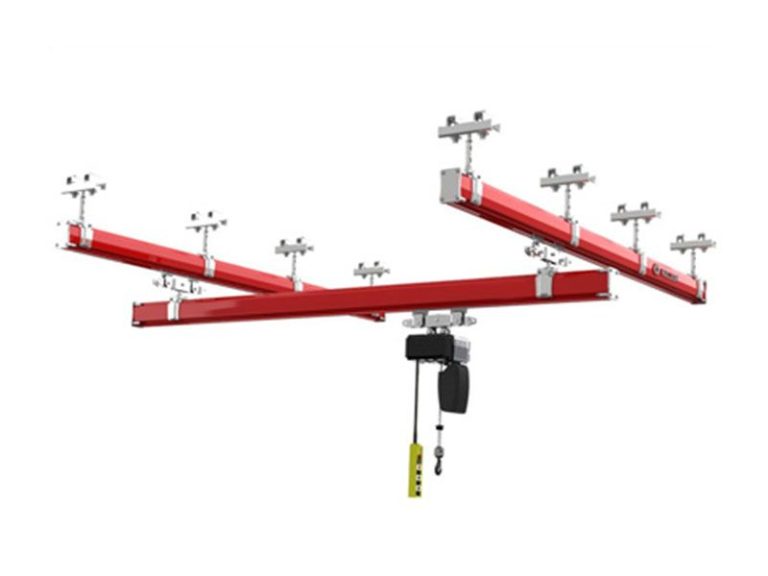

On the other hand, rail-mounted container gantry cranes are commonly used in ports and container terminals for loading and unloading shipping containers from trucks and ships. These cranes are mounted on rails and can move along the length of the dock to reach containers on different ships or trucks. Rail-mounted container gantry cranes are known for their efficiency and speed in handling large volumes of containers in a short amount of time.

One of the key differences between metallurgical bridge cranes and rail-mounted container gantry cranes is their mobility. Metallurgical bridge cranes are typically stationary and are installed in a fixed location within a facility. In contrast, rail-mounted container gantry cranes are mobile and can move along the rails to reach different areas of a port or terminal. This mobility allows rail-mounted container gantry cranes to handle a larger number of containers and increase productivity in a busy port environment.

Another difference between the two types of cranes is their lifting capacity. Metallurgical bridge cranes are designed to lift heavy loads in industrial settings, with lifting capacities ranging from a few tons to several hundred tons. Rail-mounted container gantry cranes, on the other hand, are specifically designed for handling shipping containers, with lifting capacities typically ranging from 30 to 70 tons. The higher lifting capacity of metallurgical bridge cranes makes them suitable for heavy-duty lifting applications, while rail-mounted container gantry cranes are optimized for handling containers efficiently.

In terms of operation, metallurgical bridge cranes are usually operated by a cab operator who controls the crane from a control room or cabin located on the crane itself. Rail-mounted container gantry cranes, on the other hand, are often operated remotely using a computerized control system. This allows operators to monitor and control the crane from a safe distance, improving safety and efficiency in container handling operations.

In conclusion, both metallurgical bridge cranes and rail-mounted container gantry cranes play important roles in material handling operations, each with its own set of advantages and applications. Metallurgical bridge cranes are ideal for heavy-duty lifting in harsh environments, while rail-mounted container gantry cranes excel in handling shipping containers in ports and terminals. Understanding the differences between these two types of cranes can help businesses choose the right equipment for their specific material handling needs.