Table of Contents

Advantages of Using Double Beam Bridge Cranes in Industrial Settings

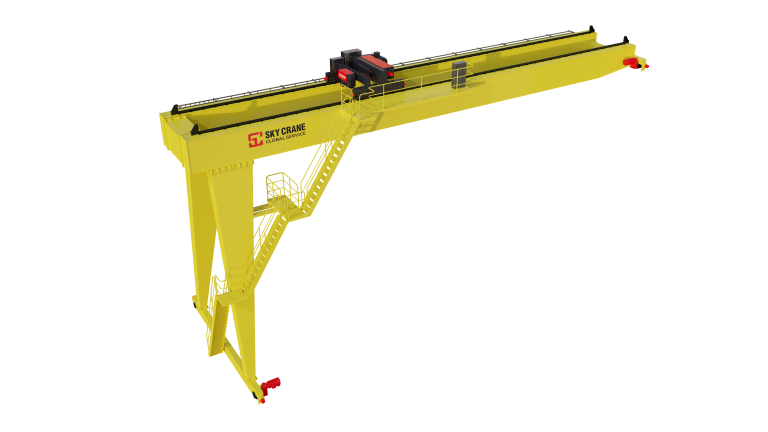

Double beam bridge cranes are a popular choice for industrial settings due to their versatility and efficiency. These cranes are designed to handle heavy loads and provide a stable and reliable lifting solution for a wide range of applications. In this article, we will explore the advantages of using double beam bridge cranes in industrial settings.

One of the key advantages of double beam bridge cranes is their ability to handle heavy loads with ease. These cranes are designed to support and lift heavy objects, making them ideal for industries that require the movement of large and bulky materials. The double beam design provides added stability and strength, allowing the crane to lift and transport heavy loads safely and efficiently.

In addition to their ability to handle heavy loads, double beam bridge cranes are also known for their versatility. These cranes can be customized to meet the specific needs of a wide range of industries, making them a flexible and adaptable lifting solution. Whether you need to lift materials in a manufacturing facility, warehouse, or construction site, a double beam bridge crane can be tailored to suit your requirements.

Another advantage of using double beam bridge cranes is their efficiency. These cranes are designed to maximize productivity and streamline operations in industrial settings. With their high lifting capacity and smooth operation, double beam bridge cranes can help to speed up the handling of materials and improve overall efficiency in the workplace.

Safety is a top priority in any industrial setting, and double beam bridge cranes are designed with safety in mind. These cranes are equipped with a range of safety features, such as overload protection systems, emergency stop buttons, and anti-collision devices, to ensure the safety of both workers and materials. By investing in a double beam bridge crane, you can create a safer working environment and reduce the risk of accidents and injuries.

Maintenance is an important consideration when choosing a lifting solution for your industrial setting, and double beam bridge cranes are known for their low maintenance requirements. These cranes are built to withstand the rigors of daily use and require minimal upkeep to keep them running smoothly. With regular inspections and maintenance checks, a double beam bridge crane can provide years of reliable service.

In conclusion, double beam bridge cranes offer a range of advantages for industrial settings. From their ability to handle heavy loads to their versatility, efficiency, safety features, and low maintenance requirements, these cranes are a valuable asset for any workplace. If you are in need of a reliable and efficient lifting solution for your industrial setting, consider investing in a double beam bridge crane for sale.

Key Features to Look for When Purchasing a Double Beam Bridge Crane

When it comes to purchasing a double beam bridge crane, there are several key features that you should look for to ensure that you are getting a high-quality and reliable piece of equipment. Double beam bridge cranes are commonly used in industrial settings to lift and move heavy loads, so it is important to choose a crane that meets your specific needs and requirements.

One of the most important features to consider when purchasing a double beam bridge crane is the lifting capacity. The lifting capacity of a crane is the maximum weight that it can safely lift and move. It is crucial to choose a crane with a lifting capacity that is suitable for the types of loads that you will be handling. If you choose a crane with a lifting capacity that is too low, you may not be able to lift and move your loads efficiently. On the other hand, if you choose a crane with a lifting capacity that is too high, you may be wasting money on unnecessary features.

Another important feature to consider when purchasing a double beam bridge crane is the span length. The span length of a crane is the distance between the two runways on which the crane travels. It is important to choose a crane with a span length that is suitable for the size of the area in which you will be using the crane. If you choose a crane with a span length that is too short, you may not be able to reach all of the areas where you need to lift and move loads. Conversely, if you choose a crane with a span length that is too long, you may be wasting space and money on unnecessary features.

In addition to lifting capacity and span length, it is also important to consider the hoist speed of a double beam bridge crane. The hoist speed is the speed at which the hoist can lift and lower loads. Choosing a crane with a hoist speed that is too slow can result in decreased productivity and efficiency. On the other hand, choosing a crane with a hoist speed that is too fast can be dangerous and lead to accidents. It is important to choose a crane with a hoist speed that is suitable for the types of loads that you will be handling.

Furthermore, it is important to consider the safety features of a double beam bridge crane when making a purchase. Safety should always be a top priority when working with heavy machinery, and cranes are no exception. Look for cranes that are equipped with features such as overload protection, emergency stop buttons, and safety limit switches. These features can help to prevent accidents and injuries in the workplace.

In conclusion, there are several key features to look for when purchasing a double beam bridge crane. Consider the lifting capacity, span length, hoist speed, and safety features of the crane to ensure that you are getting a high-quality and reliable piece of equipment. By taking the time to carefully evaluate these features, you can choose a crane that meets your specific needs and requirements.

How to Properly Maintain and Extend the Lifespan of a Double Beam Bridge Crane

Double beam bridge cranes are essential pieces of equipment in many industrial settings. They are used to lift and move heavy loads with precision and efficiency. However, like any other machinery, double beam bridge cranes require regular maintenance to ensure they continue to operate at their best. Proper maintenance not only extends the lifespan of the crane but also ensures the safety of workers and the smooth operation of the facility.

One of the most important aspects of maintaining a double beam bridge crane is regular inspections. Inspections should be conducted by trained professionals who are familiar with the specific requirements of the crane. These inspections should be done on a regular basis, ideally at least once a month, to identify any potential issues before they become major problems. During these inspections, the crane should be checked for signs of wear and tear, loose or damaged parts, and any other issues that could affect its performance.

| Number | Name |

| 1 | European electric single beam |

| 2 | MH rack crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In addition to regular inspections, it is important to keep the crane clean and well-lubricated. Dust, dirt, and debris can build up on the crane over time, causing it to operate less efficiently and potentially leading to damage. Regular cleaning with a mild detergent and water can help prevent this buildup. Lubricating the moving parts of the crane with a high-quality lubricant will help reduce friction and wear, extending the lifespan of the crane.

Another important aspect of maintaining a double beam bridge crane is ensuring that it is operated correctly. Proper training should be provided to all operators to ensure they understand how to use the crane safely and efficiently. Operators should be familiar with the crane’s load capacity, operating limits, and safety features. They should also be trained to recognize and respond to any warning signs that indicate a problem with the crane.

Regularly checking the crane’s electrical components is also crucial for proper maintenance. Electrical issues can cause the crane to malfunction or even pose a safety hazard. Inspecting the wiring, connections, and controls of the crane can help identify any potential electrical problems before they become serious issues. Any damaged or worn electrical components should be replaced promptly to prevent further damage to the crane.

Finally, it is important to keep detailed records of all maintenance and inspections performed on the double beam bridge crane. These records can help track the crane’s maintenance history, identify any recurring issues, and ensure that all necessary maintenance tasks are completed on schedule. Keeping accurate records can also help demonstrate compliance with safety regulations and standards.

In conclusion, proper maintenance is essential for extending the lifespan of a double beam bridge crane. Regular inspections, cleaning, lubrication, proper operation, and electrical checks are all important aspects of crane maintenance. By following these maintenance guidelines and keeping detailed records, you can ensure that your double beam bridge crane continues to operate safely and efficiently for years to come.