Table of Contents

Benefits of Using a 5 Ton Hook Crane in Factory Operations

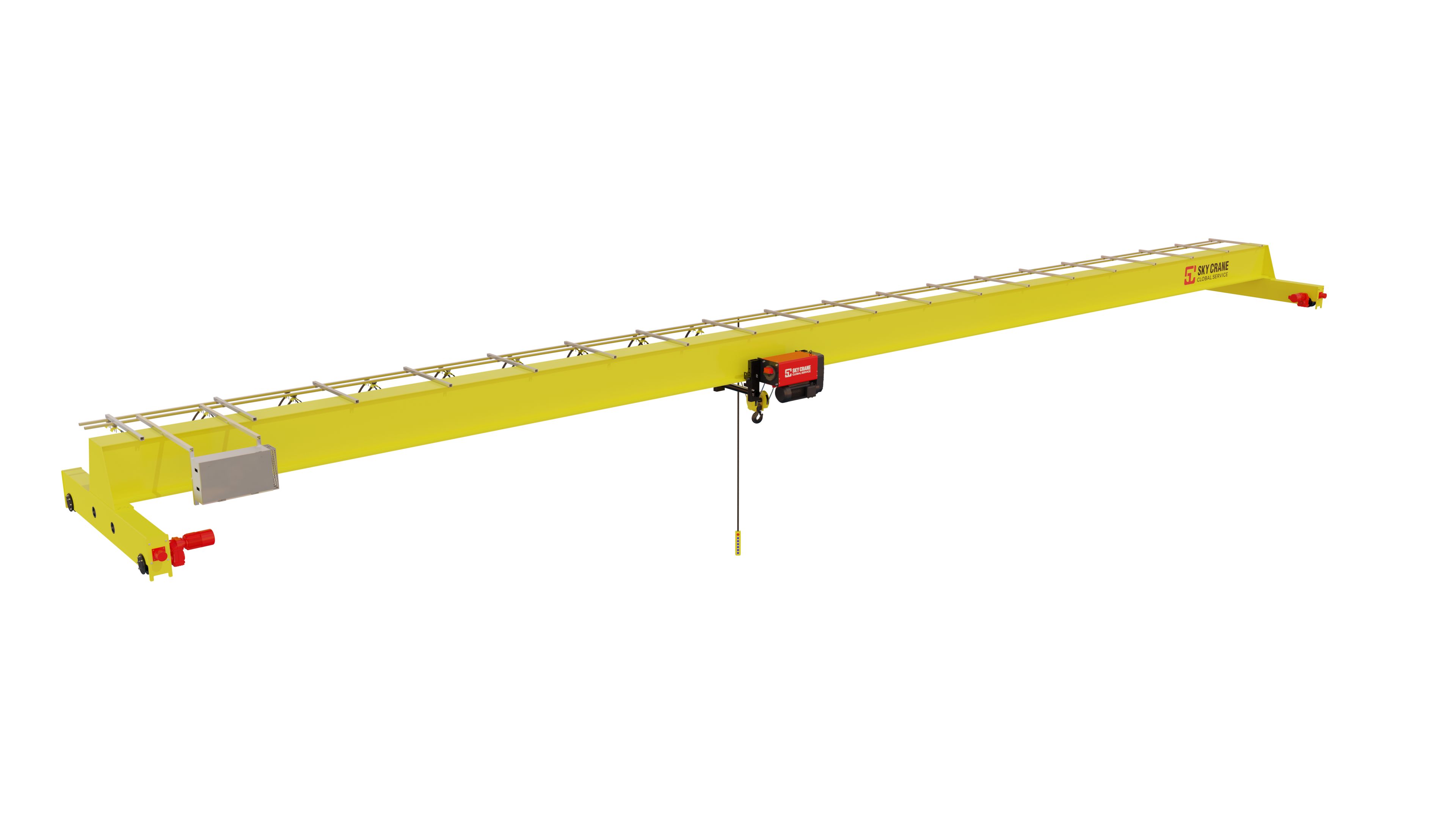

When it comes to factory operations, efficiency and productivity are key factors in ensuring the success of a business. One way to improve these aspects is by investing in the right equipment, such as a 5-ton hook crane. These cranes are versatile and can be used for a variety of tasks, making them a valuable asset in any factory setting.

One of the main benefits of using a 5-ton hook crane in factory operations is its ability to lift and move heavy loads with ease. This can help streamline production processes and reduce the risk of injury to workers who would otherwise have to manually lift and transport heavy items. By using a hook crane, factories can increase their efficiency and productivity, ultimately leading to cost savings and improved output.

In addition to their lifting capabilities, 5-ton hook cranes are also known for their versatility. They can be used for a wide range of tasks, from loading and unloading materials to moving equipment around the factory floor. This flexibility makes them a valuable tool in any factory setting, where the ability to quickly and easily adapt to changing needs is essential.

| No. | Product Name |

| 1 | European electric single beam |

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Another benefit of using a 5-ton hook crane in factory operations is the increased safety it provides. By using a crane to lift and move heavy loads, factories can reduce the risk of accidents and injuries that can occur when workers attempt to do these tasks manually. This not only protects the well-being of employees but also helps to minimize downtime and costly repairs that can result from accidents in the workplace.

Furthermore, 5-ton hook cranes are relatively compact and can be easily maneuvered around the factory floor. This makes them ideal for use in tight spaces where larger cranes may not be able to operate effectively. Their small footprint also means that they can be easily integrated into existing factory layouts without the need for extensive modifications.

Finally, investing in a 5-ton hook crane can help factories increase their overall capacity and throughput. By being able to lift and move heavier loads more efficiently, factories can take on larger projects and meet tight deadlines with ease. This can help to improve customer satisfaction and drive business growth in the long run.

In conclusion, the benefits of using a 5-ton hook crane in factory operations are clear. From increased efficiency and productivity to improved safety and versatility, these cranes are a valuable asset for any business looking to streamline their operations and drive success. By investing in the right equipment, factories can position themselves for growth and success in an increasingly competitive market.

How to Choose the Right Size Hook Crane for Your Factory (5 tons to 400 tons)

When it comes to choosing the right size hook crane for your factory, there are several factors to consider. From the weight of the loads you will be lifting to the size of your workspace, selecting the appropriate crane size is crucial for ensuring efficiency and safety in your operations. In this article, we will explore the range of hook cranes available, from 5 tons to 400 tons, and provide guidance on how to choose the right size for your specific needs.

Hook cranes are essential equipment in many industrial settings, used for lifting and moving heavy loads with precision and ease. The size of the crane you need will depend on the weight of the loads you will be lifting on a regular basis. For lighter loads, a smaller crane with a capacity of 5 to 20 tons may be sufficient. These cranes are typically used in smaller factories or workshops where space is limited and loads are relatively light.

If you will be lifting heavier loads, such as machinery or large components, you will need a larger crane with a capacity of 50 to 100 tons. These cranes are commonly used in medium to large factories where heavy machinery or equipment needs to be moved regularly. They offer greater lifting capacity and reach, making them ideal for handling larger and heavier loads.

For extremely heavy loads, such as shipping containers or large industrial equipment, a crane with a capacity of 200 to 400 tons may be required. These cranes are used in large factories or industrial facilities where heavy lifting is a regular part of operations. They offer the highest lifting capacity and reach, making them suitable for handling the heaviest loads with ease.

When choosing the right size hook crane for your factory, it is important to consider not only the weight of the loads you will be lifting but also the size of your workspace. A crane that is too large for your space may be difficult to maneuver and could pose a safety risk. Conversely, a crane that is too small may not be able to lift the loads you need to move.

In addition to size and weight capacity, you should also consider the type of crane that best suits your needs. There are several types of hook cranes available, including overhead cranes, gantry cranes, and jib cranes. Each type has its own advantages and limitations, so it is important to choose the one that is best suited to your specific requirements.

Overhead cranes are typically used in factories and industrial settings where heavy loads need to be lifted and moved horizontally. They are mounted on tracks that run along the ceiling of the workspace, allowing them to move freely across the length of the building. Gantry cranes, on the other hand, are freestanding cranes that are supported by legs or wheels. They are often used in outdoor settings or in facilities where overhead space is limited.

Jib cranes are another type of hook crane that is commonly used in factories and workshops. They consist of a horizontal arm that is mounted on a vertical mast, allowing them to rotate and move loads in a circular motion. Jib cranes are ideal for lifting and moving loads in a specific area of the workspace, such as near a machine or work station.

In conclusion, choosing the right size hook crane for your factory is essential for ensuring efficient and safe operations. By considering factors such as weight capacity, workspace size, and crane type, you can select the crane that best meets your specific needs. Whether you require a small crane for light loads or a large crane for heavy machinery, there is a wide range of options available to suit your requirements. By investing in the right size hook crane, you can improve productivity, streamline operations, and ensure the safety of your workers.

Increasing Efficiency and Safety with a New Hook Crane in Factories

In today’s fast-paced industrial landscape, efficiency and safety are paramount concerns for factory owners and managers. One way to address these concerns is by investing in a new hook crane for the factory floor. Hook cranes are essential tools for lifting and moving heavy loads, and they can greatly increase productivity while also improving safety standards in the workplace.

When it comes to choosing a hook crane for a factory, there are a few key factors to consider. One of the most important considerations is the lifting capacity of the crane. Hook cranes come in a range of sizes, from small cranes that can lift a few tons to large cranes that can lift hundreds of tons. The lifting capacity of the crane should be matched to the needs of the factory, taking into account the weight of the heaviest loads that will need to be lifted.

Another important factor to consider when choosing a hook crane is the reach of the crane. The reach of the crane refers to the distance that the crane can extend its hook to lift and move loads. A crane with a longer reach can access a larger area of the factory floor, making it easier to move loads from one location to another. This can help to streamline production processes and reduce the time and effort required to move heavy loads around the factory.

In addition to lifting capacity and reach, it is also important to consider the safety features of the hook crane. Safety should always be a top priority in any industrial setting, and a hook crane with advanced safety features can help to prevent accidents and injuries in the workplace. Some of the safety features to look for in a hook crane include overload protection, emergency stop buttons, and anti-collision systems.

Investing in a new hook crane for the factory floor can have a number of benefits. One of the primary benefits is increased efficiency. A hook crane can help to streamline production processes by making it easier to move heavy loads quickly and safely. This can help to reduce downtime and improve overall productivity in the factory.

Another benefit of a new hook crane is improved safety. By investing in a crane with advanced safety features, factory owners and managers can help to create a safer working environment for their employees. This can help to reduce the risk of accidents and injuries in the workplace, leading to a happier and more productive workforce.

In conclusion, investing in a new hook crane for the factory floor can have a number of benefits, including increased efficiency and improved safety. By carefully considering factors such as lifting capacity, reach, and safety features, factory owners and managers can choose a crane that meets the needs of their operation. With the right hook crane in place, factories can operate more efficiently and safely, leading to increased productivity and a better working environment for all employees.